Membrane bioreactors (MBRs) square measure a kind of secondary effluent treatment technology that mixes membrane filtration with biological treatment. Newer and customarily dearer than typical biological treatment choices, MBRs have historically been reserved for smaller scale effluent treatment applications. Since the late 1990’s, however, MBR use has been on the increase at facilities of all sizes.

So however do MBRs compare to traditional effluent treatment technologies? during this article, we’ll justify the foremost edges and downsides of MBRs for municipal effluent treatment applications, and explore however MBR technology may suit your municipal effluent treatment desires.

Benefits of MBRs

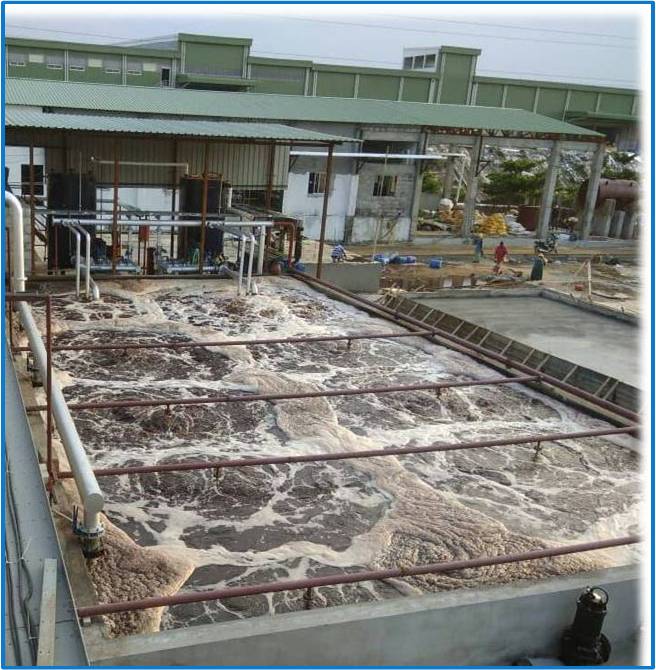

Much like typical activated sludge, MBR may be deployed as a secondary treatment step, the goal of that is to degrade the organic content of the stream, and strain suspended solids. typical approaches require multiple steps to settle the solid wastes out of answer, whereas MBR achieves solids separation a lot of quickly and utterly by employing a hybrid approach that marries biological treatment with membrane filtration. As a result, the key blessings of MBRs square measure consistent, prime quality effluent streams, and a compact size. browse on for a lot of concerning these edges.

High quality effluent

MBRs square measure extremely effective for removal of common effluent stream constituents like organic chemistry atomic number 8 demand (BOD), bacteria, total suspended solids (TSS), and even nutrients like element and element. That MBR produces prime quality effluent streams is one in every of its biggest assets, because it permits effluent treatment plants to soundly discharge to surface waterways, meet tight discharge laws, or perhaps apply treated effluent for different applications.

The suitableness of MBR technology for water reclamation applications is probably going one in every of the largest factors that has driven the expansion of MBR use at effluent treatment plants across the world—in short, as water use efforts became a lot of common, thus too have MBRs.

Small footprint

Another profit is that MBR systems square measure terribly compact. MBRs need solely concerning 25-50% of the area that a standard effluent treatment train would, because it combines activated sludge, clarification, and media filtration into one step. a part of the rationale that MBRs square measure able to reach this level of potency is that the bioreactor and filter media elements square measure designed to maximize expanse. As a result, Associate in nursing MBR system during a position to keep up a bigger biomass population in a smaller space compared to traditional activated sludge systems, a feature that each saves area and enhances biodegradation potency. As such, MBRs may be a decent fit municipalities wherever restricted area is obtainable.

Consistent effluent quality

MBRs and traditional activated sludge systems share in this they’re each biological treatment ways that deem a living biomass to perform the work of degrading dangerous organic constituents in a very stream. typical activated sludge systems deem the formation of flocs for separation functions. In short, because the biomass breaks down organic material, it forms biological solids that flocculate into larger clumps, or flocs, which will then be settled out and disposed of as solid waste. once biomass activity is compromised thanks to changes to the makeup of the effluent stream, floccule formation might not happen as supposed, and therefore the ensuing effluent are of lower quality.

By distinction, MBRs don’t rely on the formation of flocs. Instead, MBRs use filtration membranes for separation functions. For this reason, MBRs provide blessings like bigger stability in effluent quality and bigger resistance to system upset compared to traditional activated sludge systems. As such, MBRs may be a decent fit facilities whose effluent streams square measure variable or poorly degradable.

Drawbacks of MBRs

While MBRs provide some nice edges, they’ve got a number of downsides too. In short, the most disadvantages of MBRs square measure higher price and bigger operational complexness compared to traditional activated sludge systems, as elaborate below.

Cost

Perhaps the largest disadvantage of MBRs is their high capital prices and high operational prices relative to traditional effluent treatment technologies. These prices will principally be attributed to the price of membranes, energy for pumping and aeration, and proficient labor for operations and system maintenance.

But the apparently high price of MBR technology is merely a part of the story. for a few facilities, price analyses have shown that investment in MBRs will truly be more cost effective within the long run, as compared to traditional effluent treatment. the explanations for this square measure several, and may embrace reduced energy and water consumption, a smaller footprint, additionally as price blessings associated with water use, like the flexibility to sell or apply treated effluents for irrigation, process water, or different functions.

Operations and maintenance demands

One of the foremost important expenses related to Associate in Nursing MBR is that the membrane component. whereas all membranes can degrade over time and eventually need replacement, correct care and maintenance of the MBR system is crucial as a method of preventing fouling—and maximising cost-effectiveness for the MBR system as an entire by extending the lifetime of the membrane component.

As such, one in every of the downsides of MBR units is that they need a moderately high level of effort for operations and maintenance. MBR units need a daily improvement regime, which can embrace each physical improvement (e.g. air scouring, backwashing) and/or chemical improvement (e.g. application of oxidants, bases, or acids to get rid of foulants from the membrane). The precise improvement and maintenance schedule is restricted to every installation, however can typically embrace routine weekly cleanings at minimum, additionally as deeper improvement cycles a number of times per annum. Facilities considering MBR technology ought to make sure to think about however prices related to improvement chemical use and disposal, system period, and proficient labor can have an effect on the viability of MBR as a effluent treatment answer.